Shock Miser™

Protects The MWD From Shock And Vibration

Reduce shock from the drill string and improve pulse amplitude with Gordon Technologies’ patented Shock Miser™. This dual-purpose technology both protects the MWD system from shock and vibration-related failures and improves performance in extended laterals by creating a larger pulse amplitude.

The Shock Miser™ is a Plateform Foundation Game Changing Realiability Consistency Protective Adaptive

Shock Miser is more than just a sub.

The Shock Miser™ is the underlying foundation of how we package everything within our tool string. It is a way of thinking, a design system, and a technology platform that we implement in all components of the GT-MWD.

Decades of MWD research and development, combined with precision engineering, yield a fully inclusive solution to dampen shock and vibration from a broad band of damaging harmonics and frequencies. Lowering shock and vibe transmissibility allows operators to have less restrictive drilling parameters, ensuring the GT-MWD system is not a limiting factor.

Increased ROP must be coupled with an increase in data speeds. The Shock Miser™ contains a fully re-designed and patented pulser and mud pulse transmission assembly generating an industry leading pulse amplitude. This provides faster and more dense data with confidence at deeper depths than the typical MWD systems. The flow configurations are flexible and work across a wide range of flowrates. The Shock Miser™ is available in all common sizes and API thread types with custom solutions available upon request.

Perform And Preserve

Isolating MWD Tools From Harmful Shock And Vibration

The Gordon Difference

The Gordon Technologies Shock Miser offers an innovative design that greatly enhances the performance of MWD tools and also protects the equipment from demanding and harsh drilling environments.

The Shock Miser™ isolates the MWD from the drill string preserving MWD tool health, increasing expected run life, and reducing unplanned trips. The patented design is an industry leader because it addresses axial, lateral, and torsional shock and vibration. Mitigating damaging environmental exposure ensures that the operator has access to a young and healthy working fleet of assets.

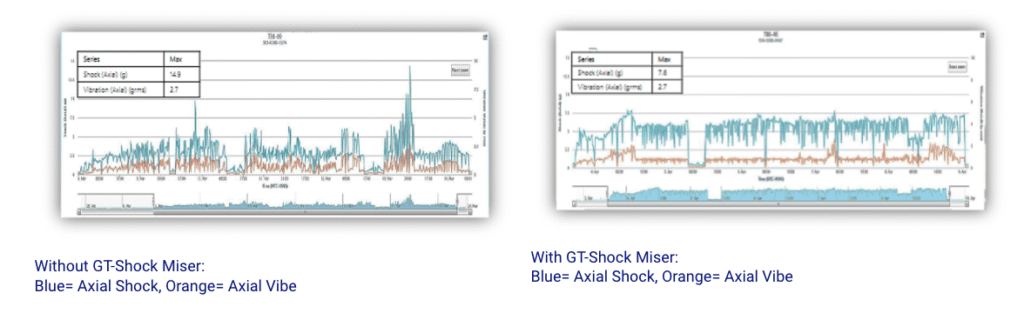

Shock And Vibration Reduction

Reduces axial shock and vibration by up to 80% and torsional and lateral shock and vibration by up to 50%.

Extended Lateral Performance

Increases MWD mud pulse amplitude by up to 300% and allows operators to reliably drill longer laterals.

Improved MWD Efficiency

Increases ROP with faster data rates and reduces rig site human error by providing standardized UBHO configurations. The Shock Miser also minimizes wear and extends life of the pulser and UBHO sleeve while providing industry leading LCM resistance.

Features

- Improves tool reliability by protecting the MWD system from shock and vibration

- Improves the quality of data transmission by creating a larger mud pulse amplitude by up to 300%

- Industry leading data rates

- Improves tool reliability by protecting the MWD system from shock and vibration

- Improves the quality of data transmission by creating a larger mud pulse amplitude by up to 300%

- Industry leading data rates

- Filters debris from the mud system, reducing the potential for MWD failures

- Highest LCM resistance in the industry – up to 40 lb/bbl of medium/fine nut plug

- Customizable flow ranges, including industry-leading high flow range that reduces cuttings debris and improves ROP

- Compatible with salt-saturated, water, and oil-based mud systems

Built For Success

More Data. Better Drilling.