GT-PWD

Drill Pipe And Annular Pressure Measurements

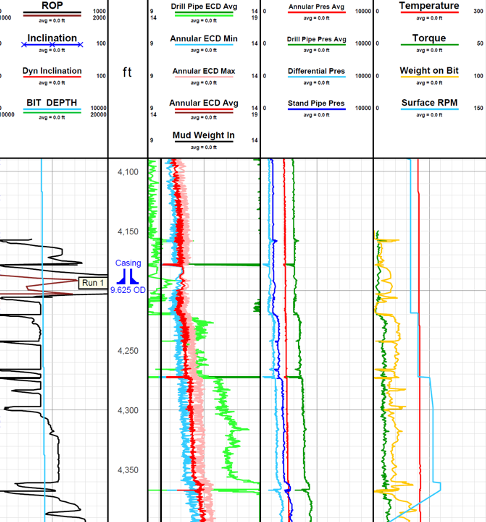

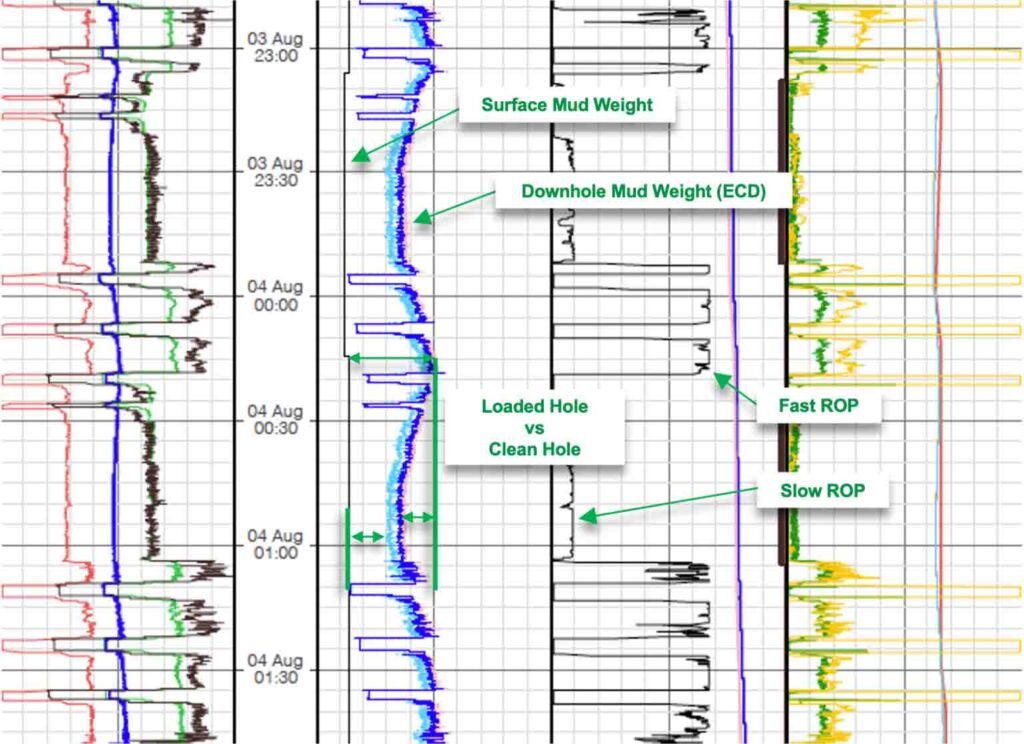

Gordon’s pressure logs assist operators in diagnosing bit failures, picking up mud motor stalls, and measuring the effects of cuttings on mud weight in hole. When coupled with WOB and TOB, adjustments can be made to drill better wells. ECD for all pressures are calculated on the surface in real-time providing information about the health of the mud system while drilling.

The Pressure Is On

Increase Production. Optimize Performance.

Dual Gamma Measurements

Gordon’s Azimuthal Gamma Ray is coupled with our standard bulk gamma sensor to enhance geo-steering decision-making.

Quality Sensor Measurements

Increase well production with accurate geologic structural interpretations. Active boundary monitoring provides immediate insights which help improve effective completion of the target zone.

Additional Applications

GT-PWD assists in optimizing motor and drilling performance, monitoring cuttings load and removal, helps to better regulate managed pressure systems and mitigate stuck pipe and lost hole risks.

Pressure While Drilling

Gordon Technologies’ 20 ksi, 175 C-rated PWD tool is designed to deliver real-time and memory measurements of Annular Pressure (including Max/Min), Drill Pipe Pressure (including Max/Min), and Annular Temperature. When coupled with WOB and TOB, adjustments can be made to drill better wells.

Quality Sensor Measurements

- Average – 10 Hz averaged over 2 seconds

- Max./Min. – Over a 2-second period

Drill Pipe Pressure (APMN)

- Average – 10 Hz averaged over 2 seconds

- Max./Min. – Over a 2-second period

Drill Pipe Pressure (APMN)

- All pressures are calculated in real-time